NANO PATCH-CLAMP (NPC)

DEVELOPMENT OF A HIGH-THROUGHPUT SYSTEM BASED ON PLANAR PATCH-CLAMP

"Patch clamping is a marvelous technique. It allows you to have access to currents across a cell in two ways: one is to look at very few channels, very few molecules, or to look at the whole cell with high resolution." Francisco Bezanilla of the University of California.

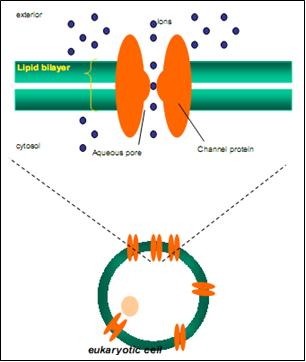

The Patch Clamp is nawdays the electrophysiological technique of election

to investigate ion channels. Ion channels are transmembrane proteins

involved in nearly all physiological processes and in many human diseases,

still today a membrane protein class in continuous exploration. The

scientific interest for these proteins is manifested by base search,

to the aim to comprise its structure, function and pharmacology, and

by applied search biomedical and farmaceutical, for the screening

of new drugs.

Figure

1. Schematic view of an eukaryotic cell and its ion channels.

Even if

traditional patch-clamp method has transformed both neuroscience and biophysics

helping usher in a new branch of drug-development research focused on

ion channels, these proteins remain an under-exploited target class, which

is in large part due to the labour-intensive and low-throughput nature

of the technique of election. However, traditional patch approache work

well in academia, where only researchers perform individual experiments.

Industry, where streamlining and throughput are important, as well as

functional genomics projects or screenings for neuroscience and pharmaceutical

research, require assays with a much higher throughput.

Several companies have released or are planning to release commercial

implementations of a new high-throughput variation on the technique, called

planar patch clamping. In these automatic devices like the planar population

array patch-clamp, PAPC, the micropipettes are replaced by pores in planar

supports. Our primary intention was to achieve a high-throughput system

based on PAPC. We rely on a Nano Patch-Clamp (NPC) device based on poly(dimethylsiloxane)

(PDMS) planar chips because of high processability and low cost of that

alternative material used instead of glass, quartz or silicon.

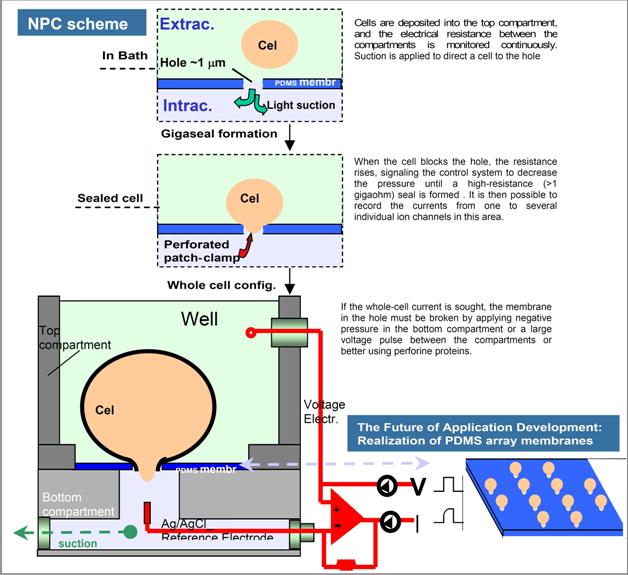

Figure 2. Schematic drawing. Establishing the whole-cell recording configuration with the prototype planar Patch-Clamp chamber. The whole procedure of preparing the whole-cell configuration is summarized into 3 states: in bath, sealed cell and whole-cell

Our microfabrication

and processing technology is sufficiently mature to produce a consistent

single-channel prototype of NPC system. Planar polymeric chips, obtained

combinig soft-lithography and air-molding, and altered to be hydrophilic

by rapid oxygen plasma treatment, have been developed. PDMS Chips will

be used in a plexiglass bench-top device. Scanning Electron Microscopy

(SEM) and precise Focused Ion Beam (FIB) systems are used to determine

the characteristics of the PDMS cell-pore interface. Our device has been

validated using both suspended and adherent cells. We are able to obtein

gigaselas and we are currently in the process of realizing whole-cell

configuration by using perforine proteins. The nearly future of application

development is the realization of a relatively low-cost PDMS array support

to perform simultaneous parallel automated recordings.

MAKING THE PDMS PLANAR CHIPS

Fabrication

of Silicon Masters

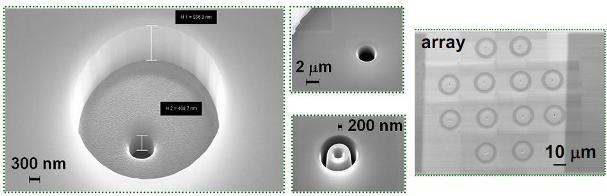

The FIB system uses a Ga+ ion beam to raster over the surface of a silicon

master. The ion beam allows the milling of small holes in the sample at

well localized sites _Fig. 3.

Figure

3.SEM

images. Creation of different micropore conformations with FIB, after

the Si-master is fixed on a pyrex support.

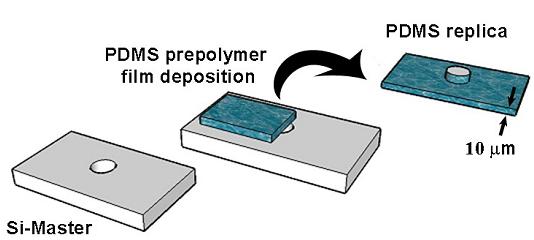

Soft

Lithography

Soft lithography is a process which allows a pattern on a master to be

embossed on soft substrate: polydimethylsiloxane, PDMS. The stamp on the

master defines the shape of the final PDMS structure. The soft lithography

is especially powerful because it is inexpensive and quick to make many

structures from the same master _ Fig. 4.

Figure

4.

Using Soft-Lithography the master is covered with PDMS prepolymer and

spinned to have 10 um thick film. After curation the PDMS replica is peeled

off from the Si-master coating it to a perfrated PDMS disch.

Air

Molding

An experimental set-up for implementing the air molding technique in a

highly flexible way has been designed, developed and tested. This apparatus

uses a nitrogen stream, channeled through the micro-perforated silicon

master, to shape a smooth micrometric pore in the PDMS thin film _ Fig.

5.

Figure

5. A: The PDMS film is perforated by air-molding then cured using

an halogen lamp.

Oxygen

Plasma

This surface treatment removes organic residues and chemically reacts

with the surface to form strong covalent carbon-oxygen bonds, which are

much more polar and more reactive than the initial carbon-hydrogen bonds.

Before making an experiment the PDMS replica is exposed to oxygen plasma

surface treatment, to change its surface from hydrophobic to hydrophilic.

Experimental

Patch-Clamp prototype chamber

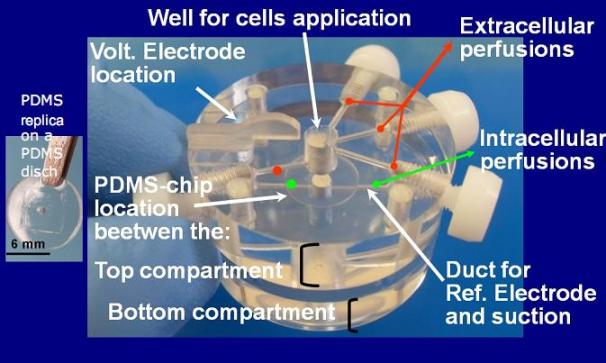

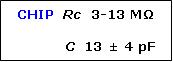

A PDMS replica is positioned between top and bottom compartments of the

chamber _Fig. 6. 10 ml of lymphocytes CEM cell suspension in extracellular

working solution (±104 cells) is added to the external well. Experiments

start when cells are attached to the PDMS-chip surface, within 5'-10'.

Figure6.

Patch-Clamp prototype chamber and PDMS replica fixed on PDMS disch.

Experimental

Results

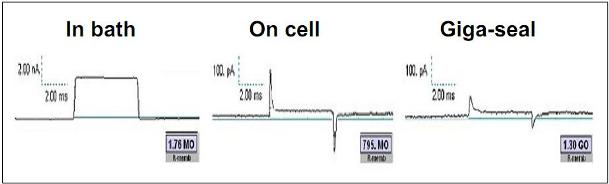

One of the recorded current in oscilloscope establishing an high resistence

seal:

"WHO'S WHO" OF THE PROJECT

Patrizia Guida is a staff researcher, responsible

of the Nano-Patch-Clamp project.

The team is directed by Professor Ugo Valbusa

of the Physics Department of the University of Genova. Dr. Luca

Repetto and Dr. Giuseppe Firpo realized

the FIB fabrication and SEM imaging activity. The project directly involves

Dr. Alessandro Bosca of the Italian Institute

of Technology (IIT) of Genova.

How to reach us

Last update

7/15/10