The rapid

development of nanofabrication techniques is dramatically increasing

the ability of manipulating fluids and molecules at the nanoscale, an

issue very promising for biological, chemical and medical applications.

Fabrication of regular controlled nanostructures

(nanochannels or nanoslits), offers new tools for investigating on phenomena

that only take place at this scale, and which could be exploited to

solve challenging technological problems such as single

molecule manipulation.

NanoMolecular Sieve (NMS) Project focuses on the development of miniaturized

nanofluidic devices for the separation of biomolecules.

Nanofabrication approaches based on low-cost materials and high-throughput

techniques have been privileged, as one of the main goals of NanoMed

Labs is the transfer of scientific results to industrial products having

high innovative and technological value.

In the framework of NMS project, sieves for the separation of long DNA

molecules have been fabricated and characterized. They take advantage

of the entropic recoil separation mechanism (Fig. 1), that was proposed

for the first time by Cabodi et al. in Anal. Chem. 2002.

They consists in nanostructures, fabricated using a Focused Ion Beam

(FIB) on a silicon master Fig. 1 a, which are then replicated using

elastomeric materials, such as poly(dimethylsiloxane) (PDMS), and soft-lithography

techniques Fig. 1 b. These nanostructures, part of lab-on-chip devices,

are then used to study the behaviour of DNA molecules in nanoconfinement

conditions Fig. 5.

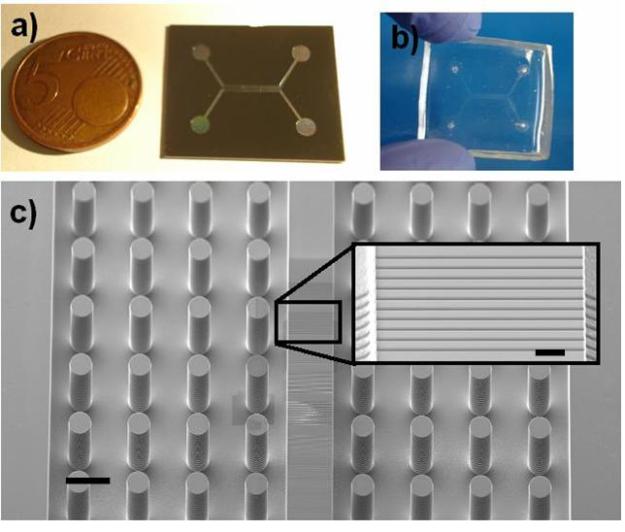

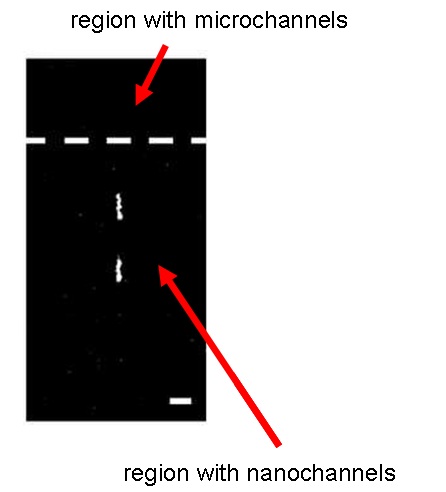

Figure

1. Picture of a silicon micromachined device (a) and of its polymeric

replica (b). SEM image of the region between microchannels where arrays

of nanochannels (shown in the inset, scale bar 15 m) are patterned using

a Focused Ion Beam, (scale bar, 50 m).

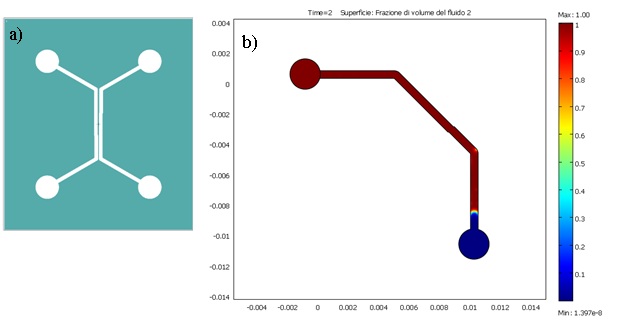

Implementation of a nanofluidic lab-on-chip for biomedical applications requires a multidisciplinary approach which results in a complex process that involves several phases: i) design of the micro/nanofluidic device layout Fig. 2 a, ii) Finite Elements Method (FEM) based simulations of fluidic and mechanical behaviour of designed micro/nanostructures, Fig. 2 b iii) design and implementation of proper nanofabrication processes Fig. 3, iv) characterization of the fabricated prototypes Fig. 4, v) processing of biological samples using nanofluidic devices and analysis of biomolecules behaviour in nanoconfined spaces.

Figure 2. a) Example of nanofluidic device layout. b) After the fabrication, polymeric devices are filled with aqueous solutions where DNA molecules are dispersed. Simulations using FEM based simulations have been performed to study the filling process of the device due to capillary forces.

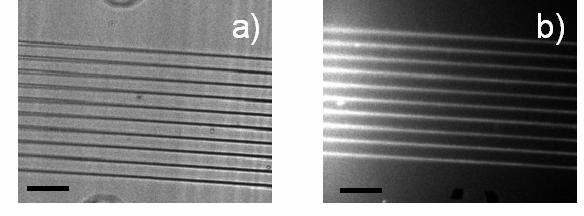

Figure

3.a)

Bright field optical image of an array of sealed nanochannels (scale

bar, 9 m). b) Epi-fluorescence image of nanochannels filled with a fluorescent

solution (scale bar, 9 m).

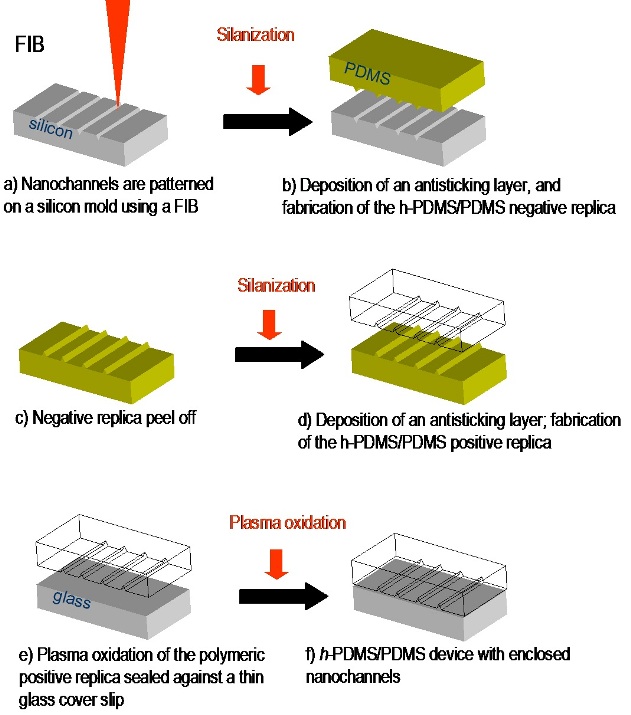

Figure

4.

Nanofluidic device fabrication process. Polymeric materials are used

in a double replica molding procedure which is followed by a plasma

oxygen activated bonding.

Figure 5. Stained -DNA molecules inserted in nanochannels. The dashed lines represent the edge of the nanostructures which are in the lower part of the picture, (scale bar, 2.5 m).

NMS project preliminary results confirmed that the fabricated nanochannels can be used to induce conformational changes on DNA chains, in fact elongated DNA molecules passing through them were observed Fig. 5.

Contact

person: elena.angeli@unige.it,

chiara.manneschi@libero.it

How to reach us

Last update

6/23/10